Termite Treatment Related

Chalk Marks:

Chalk Marks:

During a termite inspection, inspectors use chalk to mark areas of termite infestation and fungus infection inside and around a home. These markings primarily serve as a guide for termite technicians, ensuring they know exactly where to treat. In enclosed areas like attics, garages, and crawl spaces, chalk marks also create a historical record of termite activity and past treatments.

If your home has been inspected for termites, you might notice chalk markings in certain areas. If you enter your attic, for example, and see a K with an arrow pointing down, it likely indicates a pile of drywood termite droppings beneath it. If the arrow points up, it’s marking a section of framing suspected to be infested. A circle on a piece of framing usually highlights a drywood termite kickout hole, the small opening where termites push out their droppings.

Why K? It’s short for Kalotermitidae, the Latin name for drywood termites.

In your crawl space, if you find an S, it signifies subterranean termites. Though their Latin name is Rhinotermitidae, for some reason, inspectors use S instead of R.

Chalk Marks as a Sign of a Thorough Inspection

If you notice a company name and a date in a hard-to-reach area—like the far end of an attic, crawl space, or high in garage rafters—that’s a sign the inspector thoroughly checked those areas. Not all companies do this, but those that do are holding themselves to a high standard by ensuring complete inspections.

Understanding Dates and Treatment Indicators

Dates are important. If you see a K 23, it means drywood termites were found sometime in 2023. If your home was treated after that or is under warranty, any termite evidence from that time is likely considered inactive.

Around the perimeter of your home, a chalk line on a board indicates that the technician should treat that area. An arrow pointing up often means termite activity was found in second-story eaves. These chalk markings, along with the inspector’s graph, help the technician know exactly where to focus their treatment.

If multiple termite companies inspect your home and make chalk markings, it’s in your best interest to leave them in place. This ensures you receive a thorough and effective termite treatment, as each inspector’s notes contribute to a complete picture of the problem.

Drill Holes:

Drill Holes:

When locally treating for termites, technicians drill small holes—typically 1/8 inch in diameter—into the infested wood. A small amount of termiticide is then injected into each hole, and the holes are sealed with caulk or wood putty. If foam is used instead of liquid, fewer holes may be needed—but only if the technician is confident they’ve located the termite gallery. Otherwise, the foam can blow back toward the applicator.

Holes are usually drilled on the interior side of the wood to make them less visible. An experienced technician can often tell they’re drilling into termite-damaged wood based on how the bit moves through it. Drill holes can also indicate a treatment history: if multiple holes are already present, an inspector may determine the area has been previously treated and is more likely inactive.

Drill holes in sidewalks, used for subterranean termite treatments, are about the size of a dime and filled with cement patch. They’re also a clue to a home’s termite and treatment history. If an inspector knows when a treatment was completed and how long it typically lasts, they can avoid recommending unnecessary or redundant treatments.

Masking Agent

Masking Agent

A substance, typically dry cement, applied over existing termite droppings, usually in attic spaces, to indicate that the droppings are old and inactive. This helps assess the effectiveness of the termite treatment that addressed the infestation and prevents unnecessary future treatments by distinguishing past activity from new infestations.

Termite droppings are made of wood, so they don’t decompose. Without masking, there is no way to determine if droppings are old or new. If your termite company doesn’t have a masking strategy, then you should probably consider another company.

The B&G Compressed Air Sprayer

The B&G Compressed Air Sprayer

Invented in 1949 by two Purdue University engineers, Bill Brehm and George Gilmore, the B&G compressed air sprayer has become an indispensable tool in the pest control industry. Revered for its durability, reliability, and precision, it has set the benchmark for professional-grade equipment.

Unlike many tools that wear out after a few years, the B&G sprayer is built to last a lifetime. Its stainless steel tank resists corrosion, while its brass hardware ensures durability and precision even under heavy use. It’s no surprise that many pest control professionals rely on the same sprayer throughout their entire careers.

Owning a B&G sprayer is an investment. A one-gallon sprayer costs just under $400, and the accessories aren’t cheap either. A termite application tip alone is over $30, with an additional $7 for the required connecting device. But this steep price reflects its unmatched quality. With proper care, the B&G sprayer not only pays for itself over time but also ensures consistent, professional results.

Pest control often requires meticulous application, whether targeting termites in wall voids or ants along baseboards. The B&G sprayer’s design allows for highly controlled, even distribution of pesticides, minimizing waste and maximizing efficacy. Its versatility makes it suitable for indoor and outdoor use, ensuring professionals can tackle any pest issue with confidence.

While there are cheaper sprayers on the market, they lack the longevity and reliability of the B&G. Disposable or poorly built sprayers can fail at the most inopportune moments, potentially costing technicians more in downtime and replacements than a quality tool like the B&G. For pest control professionals, the sprayer is a partner in their work, and its performance directly impacts their ability to deliver excellent service.

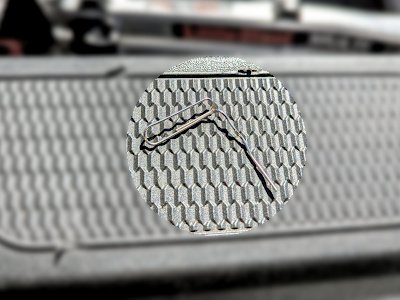

Paperclips

Paperclips

Believe it or not, one tool every termite inspector or technician can’t do without is a paperclip. Why, you might wonder? We all use B&G brand sprayers with a brass termite injection tip—and that tip frequently clogs. The best way to unclog it is with a small paperclip.

If your tip clogs and you don’t have one, you might not be able to complete your customer’s termite treatment. So if your termite inspector or technician ever asks you for a paperclip, now you’ll understand why. Just make sure it’s a small one.

Nitrile Gloves

Nitrile Gloves

These heavy-duty, chemical-resistant gloves take some getting used to—but for any seasoned termite technician, they eventually feel like a second skin. Well, maybe not on a hot day. Nitrile gloves are a staple in the termite industry. They protect a technician’s hands from termiticides and other chemicals used daily. They’re waterproof and long enough to cover the wrists, offering full protection. Tough enough to handle the harsh environments of attics, garages, and crawl spaces, yet thin enough to maintain the dexterity needed to adjust spray nozzles and other equipment. The only downside? Don’t smell the inside if they were used a couple days prior.

Caulk

Caulk

Caulk should always be used to seal drill holes after locally treating wood for drywood termites. It serves two important purposes: it helps keep the treatment chemical inside the wood and prevents moisture from getting in. On painted surfaces—especially white or beige, which are most common—the caulk also helps conceal the drill holes.

If you’re working with darker wood, using white caulk can stand out. A simple trick is to lightly rub some of the natural dirt film from the wood onto the caulk to blend it in better. The holes themselves are very small—just ⅛ of an inch—so even if they remain slightly visible, they’re not distracting. In fact, having them noticeable can be useful, since it shows exactly where the wood has already been treated and helps avoid unnecessary repeat drilling.

Clear Caulk

Clear Caulk

I used to use wood putty to fill drill holes when treating paneled ceilings for termites. Paneled ceilings are tricky because you can’t drill too deep, and since they’re part of a home’s interior, you want your work to be as inconspicuous as possible. The problem with wood putty is that it only comes in a handful of shades, while paneled ceilings come in dozens. Use the wrong shade and suddenly your one eighth of an inch drill hole looks like a dime-sized spot on someone’s ceiling.

But you know what doesn’t show—and still holds the chemical in the panel you treated? Clear caulk.

Termite Rags

Termite Rags

Rags are one of the most essential tools in termite control. We use them to clean our hands with foam soap. We use them to wipe up excess chemical. When completing a local treatment, you use your filthiest rag to wipe the excess caulk off the wood around your drill hole. We also use them to wipe the sweat from our eyes after we exit a hot attic. I couldn’t complete a termite treatment without a half dozen rags at my disposal.

Spray Rig

Spray Rig

A spray rig is a high-capacity tank sprayer powered by either a gas or electric motor. Typically mounted in a termite technician’s truck bed, it can also be trailer-mounted or made portable with a dolly. In the pest control industry, spray rigs range from 25 to 50 gallons and feature hoses between 100 and 300 feet long.

Spray rigs are essential for applying preventative borate treatments in attics and crawlspaces, as well as performing subterranean termite soil treatments. Their capacity and reach make them indispensable for efficiently treating large areas and navigating tight or difficult spaces.

Portable Sprayers

Portable Sprayers

Sprayers are essential tools for termite control companies. Portable sprayers deliver the same power as a built-in spray rig but with much greater versatility. A spray rig takes up most of a truck’s cargo space, adds weight to the vehicle, and is constantly exposed to weather and potential vandalism. Parking can also be a challenge in crowded urban areas.

For example, if a borate treatment is scheduled for a home’s attic but no parking is available nearby, a portable sprayer solves the problem—it can simply be wheeled to where it’s needed. On days without borate treatments, the sprayer can stay at the shop, freeing up truck space.

Portable sprayers are also easier to clean, which is especially important when working with borates. They’re more affordable, easier to replace, and ultimately make treatments more efficient and flexible for both technicians and customers.

Hammer Drill

Hammer Drill

Hammer drills are essential tools for termite companies when performing subterranean termite soil treatments. These drills are used to create holes through sidewalks and pavement, enabling the application of termiticide beneath the surface.

To ensure safety, hammer drills are paired with a stop box or drill interrupter—a device that automatically cuts power if the drill bit contacts grounded metal, such as pipes, conduits, or reinforced steel.

Pesticide manufacturers provide strict guidelines for drilling. For instance, drilling is not permitted in front of doors or driveways to avoid compromising the structural integrity of the pavement or walkway.

The drill holes are typically the size of a dime. Once created, a down rod is inserted into the hole, and termiticide is injected into the soil below. After the treatment, the holes are patched to restore the surface.

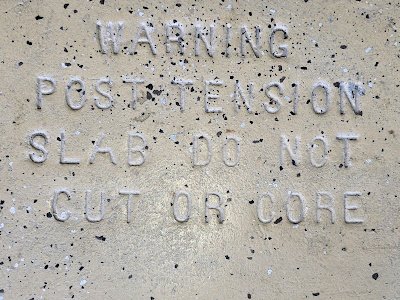

Post-Tension Slab

Post-Tension Slab

A post-tension slab is a type of concrete foundation commonly found in California. After the concrete is poured—but before it fully cures—steel cables, known as tendons, embedded within the slab are pulled tight. This tension strengthens the foundation and helps reduce cracking over time.

You can’t tell by simply looking at a foundation whether it is post-tension. In most cases, it’s identified by a stamp in the concrete near the center of the garage entrance or by a plaque mounted on the garage wall.

Knowing whether a home has a post-tension slab is extremely important. During a subterranean termite soil treatment, drilling into the slab without this knowledge can be dangerous and very costly. Severing a tendon with a drill can result in serious injury and significant structural damage. While a soil treatment can still be performed on a post-tension slab, drilling is not permitted in the garage or the interior of the home.

Drop Cloths

Drop Cloths

Drop cloths are an important part of protecting your home during an attic termite treatment. We place a large one under the attic entrance to catch any debris or borate solution that may fall while we’re working. We also line the stairs and the path our spray hose will travel. Spray hoses pick up dust and borate residue from the attic, and without a barrier they could leave marks or stains on floors and walls. Using drop cloths ensures your home stays clean while we focus on the termite treatment.

Zero Lot Lines

Zero Lot Lines

Zero lot line homes share a property line with no space in between, which can complicate termite inspections and treatments. In these cases, inspectors or technicians often need access to the neighboring property to complete their work properly.

During fumigation, this becomes especially important. If a home needs to be tented, the tent may extend onto the neighbor’s property—requiring the neighbor’s signed permission before the job can proceed.

Even when there’s a fence and each home has its own side yard, there may not be enough clearance for a technician to safely set up a ladder at the proper pitch. In those situations, the technician may need to place their ladder in the neighbor’s yard to complete the inspection or treatment. Cooperation between neighbors is essential for these jobs to go smoothly.

Rescreening Attic Vents

Rescreening Attic Vents

Rescreening is the process of replacing or adding a finer mesh screen to your attic vents, similar to the material used in window screens. This helps prevent termite swarmers from entering your attic and establishing a colony.

Since termites are attracted to attics as potential nesting sites, particularly during swarming season, ensuring that gable vents are properly screened is an effective way to reduce the risk of infestation.

Rescreening is considered a component of Integrated Pest Management (IPM) because it is a proactive, non-chemical method of termite prevention. By physically blocking swarmers from entering, rescreening works alongside other preventive measures to help protect your home from termites in an environmentally responsible way.