Wood

Cellulose

Cellulose

Cellulose is a complex carbohydrate and the primary structural component of plant cell walls. It is a polymer made of glucose molecules linked together in long chains, forming strong, crystalline fibers called microfibrils. In wood, cellulose accounts for approximately 30–50% of its composition and is concentrated in the secondary cell wall, providing strength and rigidity.

Unlike starch, which plants use for energy storage, cellulose is designed for structural support. It is indigestible to most animals, but certain microorganisms, such as protozoans and bacteria, can break it down.

Cellulose is the primary food source for termites and wood-destroying fungi. Termites rely on symbiotic protozoans in their guts to digest cellulose, converting it into usable nutrients. Wood-decaying fungi, on the other hand, produce enzymes that break down cellulose, contributing to the decomposition of dead plant material in nature.

Because cellulose is essential to wood structure, its breakdown by termites or fungi leads to significant weakening of wooden structures, making it a key concern in pest control and building maintenance.

Wood Types

Wood Types

The type of wood affected by a wood-destroying organism can provide valuable clues for identifying the insect or fungus responsible. Accurate identification is essential for determining the appropriate management strategy.

- Hardwood: Sourced from deciduous trees (those that shed their leaves in the fall), such as oak, hickory, and maple. Hardwood is primarily used in furniture making.

- Softwood: Derived from evergreen coniferous trees, including pine, fir, and spruce. Typically the wood used to produce lumber.

- Douglas Fir: Species of evergreen conifer; one of the most versatile types of softwood used in construction and woodworking. Known for its strength and durability, despite being classified as a softwood.

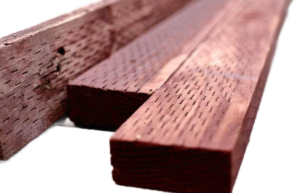

- Redwood: Milled from the coast redwood tree. Redwood is naturally resistant to decay, insects, and moisture due to its high tannin content. It is an excellent material for outdoor use, such as decking, fences, and siding.

- Heartwood: The darker, central portion of a tree trunk.

- Sapwood: The lighter, outer portion of a tree trunk.

- New Wood: Wood that has been in use for less than ten years. Many wood-boring beetles prefer newer wood due to its higher starch content, which is essential for beetle larvae survival. As the starch levels decrease over time, older wood becomes less susceptible to these pests.

- Old Wood: Wood that has been in use for more than ten years. Some beetle species are particularly attracted to older wood, which may present unique challenges.

Properly identifying the wood type and its age is crucial for effective pest management and long-term protection.

Eave Wood Members

Eave Wood Members

If you suspect termite activity but aren’t sure which part of the wood is infested, the photo on the right can help. By referencing it, you can describe the issue more accurately to a termite inspector, demonstrating your knowledge and making the inspection process smoother.

The photo highlights the most common wood components found in a home’s eaves—all of which are prone to termite infestation due to their accessibility. Fascia and fascia trim, often connected to gutters, are particularly vulnerable because of moisture buildup from leaky gutters. Rafter tails are also at risk, as their unpainted tips, which meet the fascia, provide an easy target for termites.

Decorative Wood

Decorative Wood

Architects, often without considering wood-destroying organisms like fungus and termites, incorporate decorative wood members into a home’s exterior that later become a problem for homeowners.

These features typically extend beyond the eaves and include flat, wide surfaces where moisture can collect. Every wood-destroying organism starts with excess moisture. When I inspect a home with decorative wood members, I’m surprised when the wood hasn’t been compromised.

Fungus can’t be treated—the only solution is removal of the infected wood. Homeowners are usually left with two options: replace the damaged member, which is often a temporary fix since the new wood will likely face the same conditions, or remove the feature altogether. Even when new wood is treated with borates, primed, sealed, painted, and protected with flashing, issues can still arise.

I’ve also inspected homes that use wood substitutes—stucco corbels painted to look like wood, or, believe it or not, styrofoam. I’m not saying a styrofoam corbel is easy to spot… I may or may not have accidentally pierced one or two with my termite probing pole.

Exposed Wood

Exposed Wood

Exposed wood refers to any unpainted or unstained wood framing, commonly found in attics, garages, and subareas. Because it lacks a protective coating, exposed wood is highly susceptible to termite infestation, especially in areas accessible to termite swarmers.

Attics have gable, soffit, and roof vents that allow swarmers to enter, while garages and crawl spaces also have vents that provide access. Once inside, termites can land anywhere on the exposed wood and begin chewing. Since most homeowners rarely inspect their attics and crawl spaces, termite infestations can go unnoticed for extended periods.

Borate treatments exist specifically to protect exposed wood. When applied, borates render the wood inedible to termites. If termites consume borate-treated wood, the borates kill the protozoans in their stomachs, preventing them from digesting cellulose. As a result, the termites eventually die from starvation or constipation.

Wooden Furniture

Wooden Furniture

Outdoor wooden furniture is especially vulnerable to termites. It’s often made from softer woods and exposed to moisture, creating an ideal environment for infestation.

Indoor furniture, on the other hand, is usually made from hardwoods and sealed finishes, which are less appealing to termites. However, infestations can still happen, particularly in unfinished or hidden sections like furniture legs or undersides.

For example, termite droppings were once found near a baseboard, but the source turned out to be the footing of a nearby couch. Although it was hardwood and dry, the unfinished base was enough for drywood termites to establish themselves.

Infested furniture can be spot treated, depending on accessibility. For sensitive or high-value pieces, like a piano, container fumigation may be required. These services are typically located near shipping docks, and while effective, they can be expensive due to transport and handling costs.

True Dimensional Lumber

True Dimensional Lumber

Shrinkflation may seem like a recent trend, but it has existed for years in the world of lumber.

Take a 2×4, for example—it’s not actually two inches by four inches. Instead, it measures 1 ½ inches by 3 ½ inches. Yet, if you visit Home Depot’s website and browse the “Dimensional Lumber” section, the first product listed will still be labeled as a 2×4.

Older homes built with true dimensional lumber are becoming increasingly rare. When termite or fungus damage occurs, finding replacement wood that matches the original dimensions can be challenging. However, the lumber used in older homes offers certain advantages—it was often harder, fully seasoned, and contained less moisture compared to today’s lumber. As a result, it tends to be more resistant to termites and fungus.

Pressure Treated Wood

Pressure Treated Wood

Pressure-treated wood is produced through a process that infuses preservatives into lumber to enhance its durability and resistance. This process takes place in specialized pressure-treating facilities and involves the following steps:

- Preparation: The wood is placed inside a large, sealed vault.

- Vacuum Stage: An industrial vacuum pump removes air from both the vault and the wood itself.

- Preservative Infusion: The vault is flooded with a preservative solution (e.g., copper naphthenate, alkaline copper quaternary, or copper azole).

- Pressure Application: Pressure is applied to force the preservative deep into the wood fibers.

- Draining: The preservative solution is drained from the vault.

- Curing: The treated wood is removed and placed on a drop pan for up to 48 hours to cure.

- Labeling: The wood is tagged with information about the processing plant and the type of preservative used.

Applications and Benefits

Pressure-treated wood is ideal for outdoor projects such as patios, decks, and stairways. It is resistant to termites and fungi that cause wood rot and may also be fire-retardant. Despite its treatment, it should still be painted or stained for added protection and aesthetic appeal.

Cost Consideration

Pressure-treated wood typically costs about 40% more than traditional lumber due to its enhanced properties.

Wood Substitutes

Wood Substitutes

San Diego homeowners who have experienced the damage caused by termites or wood-destroying fungi may be exploring alternatives to traditional wood. The following are some popular wood substitutes:

- Trex:

Trex is a leading brand of composite decking material known for its durability and low maintenance. Available in a variety of colors, Trex is resistant to termites and fungal damage. It is also eco-friendly, made from 95% recycled materials, including reclaimed wood and plastic film. While highly durable, Trex can fade and become brittle after prolonged exposure to direct sunlight. - Aluminum:

Textured aluminum offers a wood-like appearance and is commonly used in pergolas and patio covers. It is completely resistant to termites and moisture, making it a durable and reliable wood alternative for outdoor structures. - Styrofoam:

In newer homes, styrofoam is sometimes used in place of wood for decorative elements like corbels. Corbels are prone to wood rot due to their flat surfaces that collect moisture. Styrofoam corbels, especially when painted, are nearly indistinguishable from wooden ones, particularly on upper stories. However, they can pose challenges during inspections, as an unaware termite inspector may accidentally puncture the styrofoam while probing for damage.